Saving Money and Lowering the Cooling Load is really what an economizer does. Webster defines economize as to “reduce expenses.” In its most simplistic form, an economizer is nothing more than a device which introduces fresh outside air into a building space in a controlled manner. Under the proper conditions, the use of an economizer can save energy, and comply with local codes. Building codes often require the introduction of a specific amount of fresh outside air to match both the occupancy level of a building as well as type of building.

Saving Money and Lowering the Cooling Load is really what an economizer does. Webster defines economize as to “reduce expenses.” In its most simplistic form, an economizer is nothing more than a device which introduces fresh outside air into a building space in a controlled manner. Under the proper conditions, the use of an economizer can save energy, and comply with local codes. Building codes often require the introduction of a specific amount of fresh outside air to match both the occupancy level of a building as well as type of building.

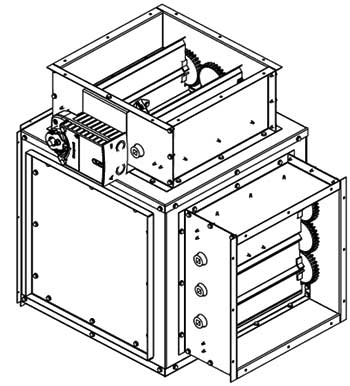

The Basic Parts of An Economizer

- An economizer utilizes an outdoor damper, indoor damper, and a barometric relief damper.

- An outdoor damper controls the volume of “Outside Air” (OA).

- The indoor damper controls the volume of the recirculating air in your space known as “Return Air” (RA).

- The barometric relief is comprised of light weight metal panel(s). This panel will only allow the building air to escape, and prevents air from entering into the building through the relief opening. Its purpose is to allow excess pressure in the building to be easily exhausted.

- A motor also referred to as an Actuator is usually included with an economizer. It is directly coupled to the dampers via gears or metal linkage rods, and physically positions the dampers. The two dampers are connected together by metal linkage rods or gears which react in unison… as the OA closes, the RA opens, and visa-versa.

- The Motor is driven from a Control Logic, and sensors.

Energy Savings — Free Cooling

An indoor air handler, or packaged Roof Top Unit (RTU) is notified by a thermostat to cool a building. If an economizer is present, and the OA heat energy is better than the indoor set-point conditions, the OA damper will open to allow the outside air to enter the building. This is referred to as free cooling because the condensing unit compressor is not required to run (or at least not as often) to cool the space. Other than a unit fan or blower, no energy is consumed, and therefore minimal cost is incurred to cool the building. Anytime the conditions outdoors is better than the indoors (cooler and/or drier), “Free Cooling” is available. Only when the outdoor temperature drops to 56°F or lower and the indoor heat is removed do you get True Free Cooling.

If the OA temperature is not cool enough, or in some cases a high level of humidity is present, the economizer will not open and the cooling will have to be achieved mechanically.

Free Cooling is what most people think of when you mention Economizers. However, true free cooling doesn’t occur until after the outdoor temperature drops below about 56°F. Anything above that may not provide 100% cooling. Actually, to truly get 100% cooling, you cannot just add cold air to a room. The warm air has to be removed. Since a typical Barometric Relief damper only relieves approximately 25% of the air introduced into a building, an economizer alone cannot provide 100% cooling.

Economizers Are Offered with Control & Sensor Packages

- Dry Bulb will monitor only the outside temperature. Therefore, it will work in conjunction with an economizer to offer “Free Cooling” when the set point temperature is detected. As previous mentioned, if your outside humidity is high, that could be problematic.

- An Enthalpy controller examines the outside temperature & humidity to prevent your “Free Cooling” mode from being less than energy efficient. It will only allow the economizer to enter into “Free Cooling” when the temperature and humidity set points are met.

- A Mixed Air or Discharge Sensor is used to monitor the mixture of the temperature combination of the Return Air and Outside Air. These sensors work in combination with the outside air sensors (Dry Bulb / Enthalpy). With the use of an economizer controller (Control Logic), all the data from the sensors are calculated, therefore allowing the economizer to self-adjust, also known as modulation.

Notice the Mixed Air Sensor and the Discharge Air Sensor depicted in the simplistic graphic above. It displays how the sensors could be utilized. You would never use both Mixed Air Sensor, or Discharge Air Sensor at the same time. However, sometimes a Mixed Air Sensor cannot be properly installed because it will become too influenced by one source of air over the other. Therefore, a Discharge Sensor would be used to ensure you are monitoring an accurate reading of the air stream mixtures. When it comes to economizer sensors, the terms Mixed Air, Discharge Air, and Supply Air are often interchangeable. The important thing to remember is put the sensor in the location that gets the best mixed air.

What’s A Mixing Box?

A mixing box is similar to an Economizer, which fulfills the exact same purpose, except a typical Mixing Box does not incorporate a Relief Damper. Economizers are often installed directly into a rooftop unit. Mixing Boxes are installed directly into duct work, or affixed to a residential style furnace, or air handler. Unlike most economizers which are designed to fit inside a rooftop unit, a mixing box is often a self-contained box which requires duct work to be directly attached to the Outside Air & Return Air Dampers.

Significant energy savings can be achieved with the proper application of economizers. The key to realizing the savings though is proper set up. This is only a summary of an economizer and all its applications. We’ll cover more of this along with associated accessories like Power Exhaust, CO2, and Energy Recovery Ventilation Units (ERV) in later blogs.

Trackbacks/Pingbacks